Year-end technology trends

Inkjets are slowly become user-friendly -- and may soon be dramatically faster

By Anand Parthasarathy

December 15 2014: Two weeks ago, in this spot, we reviewed the state of the art in home and small office laser printers and found the technology barely evolved from its early days. Things are a little better when we look at inkjet printers, though here too, the industry has remained notably consumer-unfriendly -- till recently.

In 1977, an engineer at Canon, perfected the thermal inkjet technique that still drives all consumer printers from that company as well as from makers like HP and Lexmark. The print cartridges contain a series of tiny chambers, each with its heater. When a pulse of current is passed through the heating element, the ink vaporises into a bubble and drops onto the paper.

A rival 'cold' technique used by Epson and Brother, uses the piezo electric effect instead of a heater: When a voltage is applied, a piezo ( meaning 'squeezed') material changes shape and pushes a drop of ink out of the nozzle.

Till a decade ago, entry level colour inkjets came with a single multi-colour cartridge -- and customers resented the wastage: If one colour of the three was used up, it stopped working. Then makers offered separate cartridges for black and the three primary colours -- but here too industry avarice was at play: cartridges notoriously indicated they were empty, even though substantial ink remained. Till customer outrage stopped it, some even installed 'killer' chips that prevented them from bring reused by refilling.

This year Epson became the first printer maker to offer ink tank systems in its consumer range of inkjets: While ink cartridges typically contain about 10 ml of ink, these printers let users pour ink into four tanks from 70 ml bottles which cost around Rs 440 each. It's not rocket science -- and most buyers will appreciate the savings -- considering that printing ink, millilitre for millilitre, is costlier than champagne.

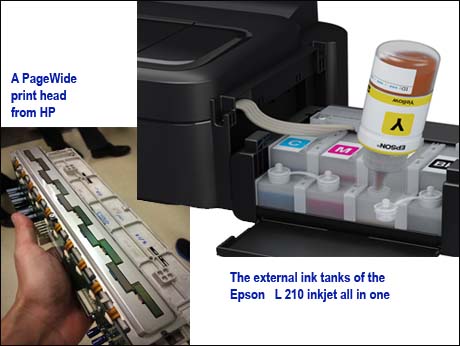

I recently tried out one of the 7 tank ink printers Epson offers -- the L210 -- an A4 print-scan-copy machine which is priced Rs 10,499. The tanks are fitted on the outer wall and filling them is a no-brainer. You can lock the tanks during transportation. The company suggests you can get about 4000 pages from a set of bottles, which means around 25 paise for a colour page -- not bad! If you need the wireless feature you have to pay another Rs 5000 for the L355. The prints are churned out at between 15 and 25 pages a minute(ppm).

High speed printers

These speeds are about par for consumer inkjets -- but the irony is the industry developed new technology that can triple this speed, even 6 years ago. This is done by making the cartridge as wide as the paper carriage. Instead of the head zipping to and fro across the paper width, it now stands still and prints the full page width at one go. Only the paper moves forward one line at a time.

The technology was developed almost simultaneously by HP which initially called it Edgeline, later PageWide -- and by an Australian ( now San Diego, US-based) outfit called Memjet. Print speeds of up to 75 ppm have been achieved by these wide print heads which house 40,000 to 70,000 ink nozzles. Canon and Xerox which have licensed the Memjet technology and HP using its own technology, have launched these zippy printers -- but mainly for the high-end production print market.

The cheapest PageWide printer today costs more than Rs 40,000, but it looks as if printer makers might slowly trickle down the technology to the small office sector. Clearly, the lay consumer -- like Mr Barkis in David Copperfield --is 'willing'. High speed inkjet printing is a technology whose time has come.

For a few days, a short video on Memjet technology, in our Tech Video spot on the home page